Optical fibers are about the diameter of a strand of human hair and when bundled into a fiber-optic cable, they’re capable of transmitting more data over longer distances and faster than other mediums. It is an excellent vehicle for high-speed data transmission as long as light transmission is efficient – even across connector assemblies. This translates to a need to polish connector end faces to optimize performance.

A fiber-optic cable contains anywhere from a few to hundreds of optical fibers within a plastic casing. Also known as optic cables or optical fiber cables, they transfer data signals in the form of light and travel hundreds of miles significantly faster than those used in traditional electrical cables.The light beam travels down the core of the cable. The core is the middle of the cable and the glass structure. The cladding is another layer of glass wrapped around the core. Cladding is there to keep the light signals inside the core.

Fiber optic cables carry light signals in modes. A mode is a path that the light beam follows when traveling down the fiber. There are single mode and multimode fiber cables. Single-Mode has a narrow core (eight microns or less), and the index of refraction between the core and the cladding changes less than it does for multimode fibers. Light thus travels parallel to the axis, creating little pulse dispersion. Telephone and cable television networks install millions of kilometers of this fiber every year.

Multimode fiber is the other type of fiber optic cable. It is about 10 times larger than a single mode cable. The light beams can travel though the core by following a variety of different paths, or in multiple different modes. These cable types can only send data over short distances. Therefore, they are used, among other applications, for interconnecting computer networks. There are four types of multimode fiber optic cables, identified by “OM” (optical multimode). An industry association designated them as OM1, OM2, OM3 and OM4. They are described by ISO/IEC 11801. OM4’s standard was approved by TIA/EIA 492AAAD. Each OM has a minimum Modal Bandwidth requirement.

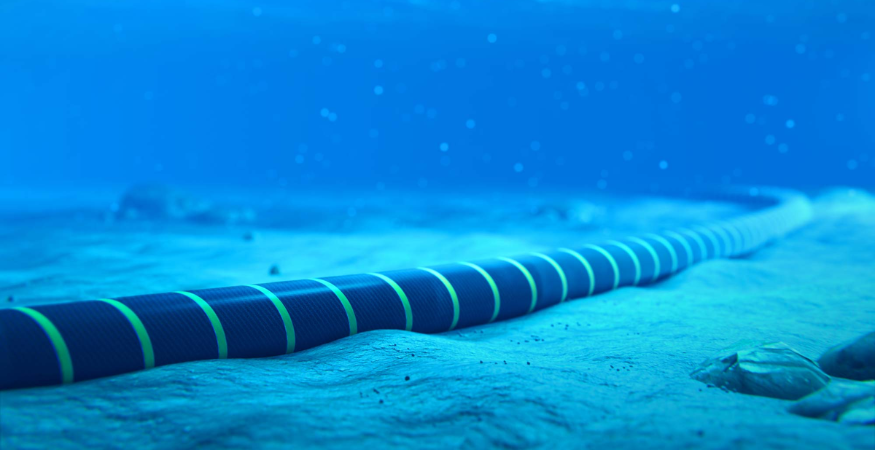

A Subsea cable is a fiber optic cable laid in the ocean, connecting two or more landing points. Rarely much wider than a garden hose, today cables generally comprise of the optical fibers that carry the information, which are then covered in silicon gel, then sheathed in varying layers of plastic, steel wiring, copper, and nylon in order to provide insulation to protect the signal and protect the cable from damage from wildlife, anchors & fishing, or weather & other natural events. The cables are laid using ships that are modified specifically for this purpose, transporting and slowly laying the ‘wet plant’ infrastructure on the seabed. These special ships can carry thousands of kilometers of optical cable out to sea. A special subsea plow is also used to trough and bury submarine cables along the seabed closer to shorelines where naval activities, such as anchoring and fishing, are most prevalent and could damage subsea cables.